Agri-PV FAQ

Frequently asked questions

We are delighted that you are interested in our Agri-PV products and services!

As you think about using Agri-PV and the associated factors and framework conditions, you will doubtless have plenty of questions covering a variety of areas which will play a major role in your decision-making.

To help you, on this page we have compiled lots of frequently asked questions. If there is a question or topic that you cannot find here, please get in touch with us directly via our contact form at the bottom of the page and we will get back to you as soon as possible.

General Questions about Next2Sun Agri-PV

Specific questions by interest or user group

Search by topic/term

The Next2Sun Agri-PV concept

- The PV concept

- Construction & difference to conventional south-facing PV systems

- Areas of application and use

- Where can Agri-PV systems be installed?

Agriphotovoltaics falls under the umbrella term ‘open area photovoltaics’ and covers concepts that enable photovoltaics and agriculture to share use of the same space.

The DIN SPEC 91434 technical rule ‘Agri-photovoltaic systems – requirements for primary agricultural use’ can be downloaded for free in various languages from the following link:

https://www.beuth.de/en/technical-rule/din-spec-91434/337886742

In densely populated countries like Germany and Austria, competition for land is becoming increasingly fierce between the energy and agricultural industries. To combat this, agriphotovoltaics concepts enable areas to be used simultaneously for both energy generation and agriculture, thus increasing space efficiency. Various investigations have shown that installing PV modules has a positive impact on agricultural yields, thanks to the shade and wind protection they provide. This creates a genuine win-win situation that both generates additional energy and benefits the farm.

We at Next2Sun AG have developed a vertical, stable, steel frame system for PV modules, consisting of two posts and three beams. These hold two stacked bifacial glass-glass modules. The total height of the frame is flexible and adaptable, and generally sits around three metres above the ground. The frame design was developed to ensure functionality, easy and flexible assembly, and a long service life. The patented post-and-beam system from Next2Sun Mounting Systems in particular minimises module shading thanks to the elevated system.

Together with the glass-glass solar modules used, the system as a whole also has a very long shelf life. The system is designed to meed high static requirements resulting in particular from wind loads. Project-specific adjustments enable it to be used virtually anywhere on the planet. The stand system can be used for agriPV concepts, but also in other areas, for example as a fence (solar fence) or a private consumption system.

The modules in our Next2Sun plant system are stood vertically. Special frameless glass-glass modules are used for this. These bifacial modules are light-sensitive on both sides. The vertical design of the modules with a row space of at least eight metres in between ensures a very low level of overbuilding of the area (ground space / overbuilding of the area approx. 5%). Conversely, more than 90% of the space remains available for agriculture use and environmental upgrades. By comparison, the overbuilding of the area for conventional south-facing systems sits at over 70% (= projected module area on the ground). If the clearance between the lower edge of the modules and the ground is 0.8 to 2 metres, there is no likelihood of any meaningful agriculture use.

In addition, the vertical design (particularly in an east-west orientation for the front and back of the modules) creates an innovative feeding profile, combined with an additional technical yield [kWh/kWp] compared with south-facing photovoltaics systems.

Our system enables dual use of the space for both solar power production and agriculture. This agriculture use can take the form of crop cultivation, pasture management, grassland management or environmental upgrades.

The Next2Sun APV concept can be installed in any azimuthal orientation. However, the ideal orientation is heavily dependent on the local conditions and will be recalculated for each new site.

The Next2Sun system concept reaches its full potential in an east-west orientation, meaning that electrical power is primarily generated in the morning and evening, at times of day when demand is highest. This also allows the highest prices to be achieved with direct marketing.

The Next2Sun system concept still achieves good electricity yields in other orientations.

Modules will be between 1.80 metres and 2.80 metres in height, depending on whether they are arranged as one or two rows.

Each PV module is 2.20 metres in length, and the length of the entire row depends on the site size (row breaks are incorporated into detailed planning).

A module row will be approximately 0.2 metres deep/wide – the number of rows depends on the available space.

The maximum dimensions of a Next2Sun APV system are always based on numerous local factors and are assessed in each individual case. We generally operate in the following area:

Height: maximum 3 modules (= 3.80 metres)

Area size: not pre-determined

The frame system is a Next2Sun patent.

There are no set rules – particularly interesting and suitable options are generally less-favoured areas such as open space by railway lines, motorways or industrial zones, but reserve agricultural space is also well suited (although this is always a case-by-case decision).

Our standard variants have two bifacial PV modules stacked on top of each other. Depending on the wind load, the environmental conditions and economic aspects, it would also be possible to have one or three modules.

As for conventional PV systems, we have to install a fence around our system. This is required by insurance.

The cabling for each module is laid in the middle beam (U-rail). This provides the cabling with sufficient protection from weather, grazing animals and wild animals. If desired, module cables can also be given optional additional protection with a plastic cover.

We use our patented elevated system of steel posts, piled using a hydraulic pile driver. The foundation depth depends on the load (wind), the ground conditions and the statics of the frame itself. Generally, no additional foundations are required. In individual cases (underground rock), it may be necessary to use a core drill to make a hole for the foundation, which is then filled with concrete.

First the foundation must be examined, as our system is subject to different horizontal loads than conventional solar parks. The systems themselves consist of two different segments. The first four or five posts in a row have a stronger profile. These are piled 2 to 2.5 metres deep and must withstand the wind load incurred at the end of a row. From the fifth post onwards, the weaker piling posts are piled to a depth of 1.6 metres.

Only bifacial PV modules are used for Next2Sun systems.

A few years ago we were installing Jolywood modules, now we are using Luxor and Akcome modules. Certain criteria must be met for us to choose to install a module.

The place of manufacture is almost exclusively China.

Material used: silicon

PV type: cadmium, monocrystalline or polycrystalline modules? N-type PV

Dimensions 2.0 x 1.0 metres

The front of the modules is dark blue and the back is light blue.

Potential land use options beyond Agri-PV

- Almost full agricultural use available

- Land usage for Agri-PV system

- Different mounting options

- Prospective yields with agriculture use

Variable spacing between rows of at least eight metres enables various agriculture use concepts. The row spacing is individually determined based on the local requirements and economic considerations.

Various forms of grassland use are available:

- Hay meadows (hay or silage use)

- Pasture farming (cattle, sheep or similar)

- Biomass and material use

- Arable land is also an option

You must keep around 0.5 metres away from the module rows. Grassland management can be up to 20 centimetres from the module row posts, if the tractor has onboard GPS support.

As the bottom edge of the module sits around a metre above the ground, there is no issue with machine tilling of the soil. However, the crops cultivated should not significantly exceed a metre of growing height.

This far our systems have only been used for grassland farming. Farming machinery for this is equipped with suitable rubber lips, reducing the risk of flying stones to a minimum.

We have not yet identified any module damage following the mowing process. During the prototype phase, we deliberately provoked flying stones (including for potential installation next to roads) and no damage was detected.

In general, we agree in advance with farmers that they will not have to pay for small amounts of damage (e.g. up to 1000 euros).

Up to 90% of the solar park area can still be used for agriculture. The gap of at least eight metres between the rows enables the use of standard agricultural machinery, ensuring efficient work management. This significantly minimises excessive land consumption.

Variable gaps between rows of at least eight metres enable various agriculture use concepts. The row gaps are individually determined based on the local requirements and economic considerations.

The open area system is suitable for grazing cattle, sheep or chickens.

Most crops will not be significantly impaired by the approximately 15% reduction in sunshine to the area, and could even benefit from it in very dry years. Examinations of growth in existing systems have already shown that improved water balance and wind protection thanks to greater shade led to significantly higher hay yields.

The piling posts are piled a little over two metres into the ground. The piling does not affect crop cultivation, as land managers leave a distance of 0.5 metres from the module rows.

In the development plan, the area between the module rows is generally set as agricultural land. In Germany and other European countries (AUT, LU etc.), there are regulations stating that the farmer retains the key area payment for the majority of spaces within agriphotovoltaics systems. The milestone in Germany will be the implementation of GAP – the Direct Payment Implementation Ordinance – from the 2023 claim year, stating that 85% of the area within agriPV continues to be agricultural and will receive EU subsidies. The remaining 15% of the premium rights come from the operators of Next2Sun systems, by agreement.

By current understanding, the Next2Sun system concept has no effect on the water balance of agricultural land. Around 99% of the area is not overbuilt, meaning that precipitation can trickle uninterrupted into the soil. The vertical elevation of the PV systems only produces a very small rain shadow in high winds, which has little effect on general soil moisture levels.

Practical testing from recent years has shown that slight shading changes the agricultural yield in row space. During dry years this can result in increased yields (especially in grassland) due to a higher level of water being available to the plants. In damp and less sunny years, the shade could theoretically also reduce yields to an extent (particularly for crop cultivation). These effects could be stronger in more shaded areas (near to the modules). Further investigations will be conducted into this in coming years.

GPS-supported control for agricultural machinery is advisable within a Next2Sun agriPV system, as it enables the entire length to be worked at an optimum distance from the module row.

Currently, a lawnmower or grass trimmer is used to mow beneath the module rows. This involves high staffing costs, which we want to reduce in the future via tests with a cane cleaner. This device comes from orchard and vineyard cultivation and will automatically fold round the posts to mow. Mowing is performed once or twice a year.

Practical experience from recent years has shown that dirt and dust is cleaned off vertical modules very well by rainfall.

First of all, it should be noted that any intrusion on the landscape with overbuilding and/or sealing of the ground must be counterbalanced. As the overbuilding of up to 5% the area (actually just 1% by the agriPV itself) with the vertical system concept is extremely low and the structuring of the agricultural area with grass strips below the modules offers environmental upgrading, all in all the environment in the area is upgraded.

No offsetting measures are generally required with the Next2Sun system concept. These are separate from functional compensation measures, which are considered in individual cases. These include measures to avoid glare effects and improve landscape integration, as well as to balance the habitats of individual bird species.

There has not yet been a final assessment of whether flower and grass strips are eligible for funding (e.g. Under EU greening measures or agri-environmental schemes).

The maximum building density is 15%. In addition, it must still be possible to work the area using standard agricultural methods, machinery and equipment.

Yes, all agricultural products coming from the area can be used.

We have had cattle grazing in our testing facility for two years. In our system, the cable wires are all run in the U-rail (middle crossbeam), ensuring that they are very well protected. Only the inverters require technical protection. This is generally achieved using a simple pasture fence stretched around the inverter. Horses behave similarly to cattle and do not pose a problem for the system. Projects have already been implemented in situations like these in Austria.

Thus far we only have experience with grassland farming. In the future, we are planning to establish research projects examining crops. However, we expect potatoes, various types of beets, carrots, legumes, special crops (with the exception of maize) and low-growing cereals (approx. 1 metre) to be very compatible with our system.

Electricity yield

- Yield by comparison and over the day

- Yield per hectare

- Weather dependency and seasons

- Purchasers and remuneration

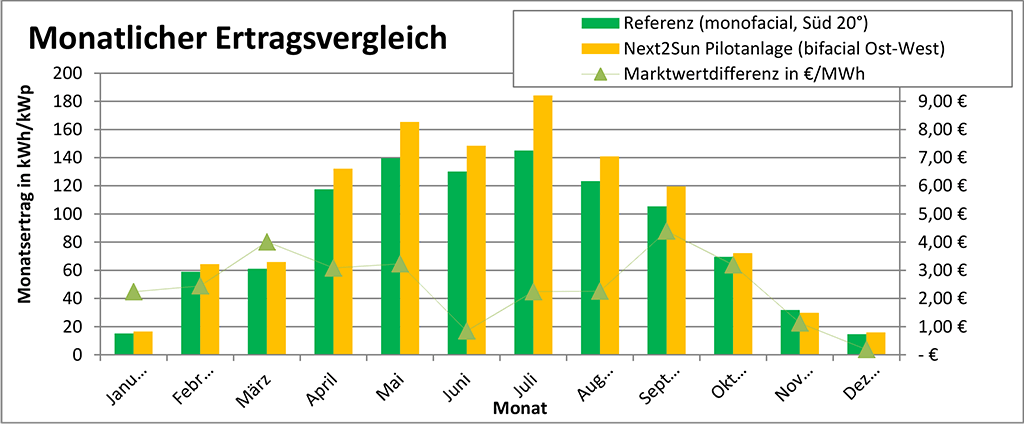

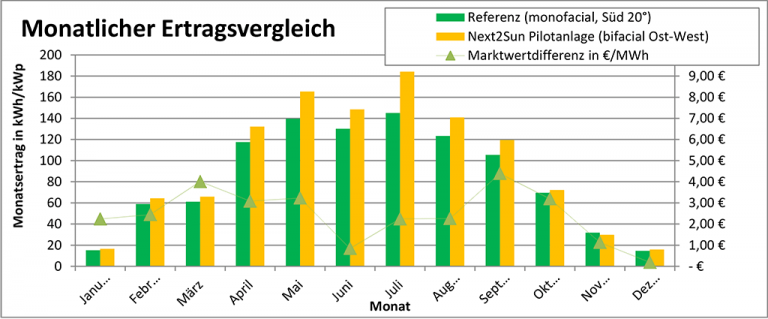

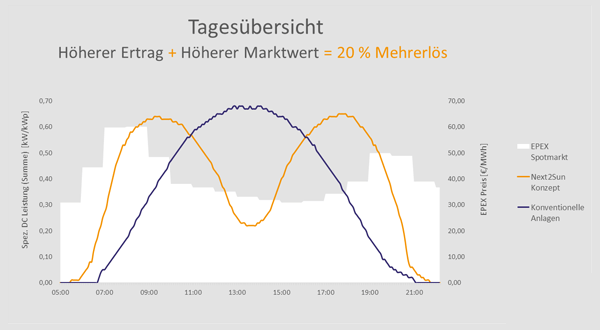

The east-west orientation of the PV module rows means that electricity is primarily produced in the morning and evening. depending on the module type used, 5% to 15% higher specific electricity yields are achieved per kW. This means that Next2Sun systems are a long way ahead of traditional south-facing photovoltaic systems in terms of yield.

The east-west orientation means that systems using the Next2Sun concept feed in power when conventional south-facing PV systems have low production levels. This greatly lightens the load on power networks, particularly at lower voltage levels.

Next2Sun systems can therefore feed in power even in areas where networks are running at near capacity from wind and conventional PV systems.

The feeding profile of the Next2Sun system matches the daily curve of the electricity price on the electricity exchange. This means that you also directly benefit from market activity. Usually, feed-in at midday will achieve a lower price than in the morning and evening.

As a result, you will achieve an average of 5-10% higher annual profits with Next2Sun systems. Combined with higher yields from the east-west orientation, this can mean up to 25% more revenue per kW of installed system power.

The vertical, bifacial glass-glass modules are able to more effectively generate power from diffuse light (when skies are cloudy) than most monofacial modules. In addition, ground with a particularly high albedo (i.e. level of reflectivity) can offer even greater yields. Particularly bright substrates (such as snow) offer particularly high reflectivity.

The precise generation profile is dependent on numerous local parameters, making it impossible to state anything for certain. With our systems, we ensure that the generation profile suits the relevant requirements. In general, PV systems produce less electricity in the winter than in the summer as there are fewer hours of sunshine per day.

The feeding profile of the Next2Sun system matches the daily curve of the electricity price on the electricity exchange. This means that our system also directly benefits from market activity. The typically lower electricity prices at midday and higher prices in the mornings and evenings mean that our systems using the Next2Sun concept achieve higher average revenue – we obtain market profits on the electricity market that are 5% to 10% higher than for conventional PV systems.

A row spacing of 10 metres can be expected to produce a yield of approximately 0.4 MW per hectare.

This means space requirements of 2.5 to 3 hectares per 1 MW of power, with 98% of the space remaining available for agriculture use.

The front sides of the module currently have an output of 465 W, whilst the reverse with its tailored HJT modules built in by us has 90% to 93% bifaciality and thus another 430 W of output. With custom products, bifaciality of up to 98% can be achieved. We currently only use HJT solar modules in our systems.

The energy generated at the solar park is fed into the medium-voltage grid. The electricity is then distributed and consumed on a regional level. As electricity flows into the power grid from various generating plants, an electricity mix from various generation profiles comes through at every plug. A vertical, bifacial east-west system can primarily generate power in the mornings and evenings, thus increasing the proportion of renewable energy consumed locally compared with conventional south-facing solar power plants.

Yes, agrivoltaic systems are generally eligible for commission as “special solar installations” in accordance with §37, Para. 1 No. 3 a, b, c. Consequently, they only have to comply with the stipulations of the Federal Network Agency and either have a combined agricultural use of arable land or permanent grassland or the simultaneous cultivation of permanent crops. Installations on areas particularly worthy of nature conservation, such as Natura 2000 areas, are not eligible for commission.

Our system hits peak power in the morning and evening, but still produces a certain yield in the middle of the day. If the grid connection point is completely at capacity, it will not be possible to connect a Next2Sun system unless it can be capped during midday hours. If the grid connection point is too overloaded for a conventional system, a Next2Sun system can still be connected.

Efficiency

- Profitability

- Level of investment

- Added value

- EEG commission

The installable power per area is lower than with south-facing systems due to the row spacing, but the area can continue to be almost fully used for agriculture, and lower lease payments are due to land owners.

The vertical elevation allows for the use of diffuse radiation, which makes up around 50% of all radiation in Germany, enabling more electricity to be generated per installed power than with conventional systems. In addition, higher exchange prices can be achieved outside of the midday generation peaks of south-facing systems, benefitting the system operator and offsetting the marginally higher costs.

The investment costs for the turnkey installation of vertical Next2Sun systems depend very much on the size of the system.

Compared to conventional monofacial south-facing PV systems, large Next2Sun systems incur approx. 10 – 20 % additional costs for the system installation. The additional yield from direct marketing and the additional technical yield of vertical bifacial systems means that they offer additional revenue during the operating phase. The price difference between conventional PV and our system is currently around 20-25%. However, trends suggest that prices will drop further in the near future, putting cheaper bifacial modules on the market, with another positive impact on overall costs.

Next2Sun Projekt GmbH develops agriphotovoltaics projects at its own cost and risk. This is creating jobs all over Germany.

Once construction rights are awarded, primarily regional or grassroots investors are sought to operate the solar park for the long term. These may be cooperatives, individuals or municipalities. Regional utility companies or other companies are also considered.

If we have sparked your interest in financial involvement in a solar park, please get in touch with us.

The stated service life of a Next2Sun system is 30-40 years. This means that it is longer-lasting than conventional south-facing ground-mounted PV systems (25-30 years).

The expected absolute electricity yields depend on various geographical and also technical parameters at the site. The relative electricity yields per module installed may for example then be dependent on the module’s orientation, the module’s output, and other geographical conditions. Our projects include creating a yield forecast via a detailed simulation before a system is installed.

The choice of row space is key for the generator output that can be installed. We have noted that the working width of machinery in conventional agriculture (field sprayers and fertiliser spreaders) is becoming increasingly large for economical reasons. We are currently working on usage concepts that can be implemented with row spacing of 30-34 metres. These are pilot projects that are not transferable to every location. In our view, row spacing of 8 to 20 metres currently represents the sweet spot between solar power production and agriculture.

Non-EEG systems must be approx. 10 MW (20-30 ha) in size unless they have received any additional funding. However, the size is site-specific, dependent on factors such as the location of the grid connection point. EEG systems can be profitable at approximately 3 MW (7-10 ha), depending on the site.

Our specific yield per kW is higher than conventional modules, because our modules are bifacial. In conventional systems, PERC modules with a bifaciality of 65% are often used. Given the east-west orientation, we need n-type modules with 85% bifaciality. Heterojunction solar modules with bifaciality of up to 98% are better, but currently more expensive than n-type modules. In the future, we expect heterojunction modules to be more economical.

Yes, agrivoltaic systems are generally eligible for commission as “special solar installations” in accordance with §37, Para. 1 No. 3 a, b, c. Consequently, they only have to comply with the stipulations of the Federal Network Agency and either have a combined agricultural use of arable land or permanent grassland or the simultaneous cultivation of permanent crops. Installations on areas particularly worthy of nature conservation, such as Natura 2000 areas, are not eligible for commission.

These depend very much on the size of the system and are approx. 10 – 20 % higher for large Next2Sun systems than for conventional systems due to the high wind loads. Alongside the slightly more expensive modules, this is the reason for the system’s higher costs. There are significant amortisation benefits from the higher electricity yields, better feed-in tariffs (approx. 0.3 ct/kWh more) and longer service life.

Nature, environment and impact on the landscape

- Effect of Agri-PV on nature and the environment

- Impact on bird life

- Soil quality and biodiversity

- Impact on structure of the landscape

As well as the aforementioned dual use by photovoltaics and agriculture, the Next2Sun system concept also enables environmental upgrades.

A habitat for diverse flora and fauna can be established in the non-agriculture-use areas below and right next to module rows via strips of grass and flowers. By adding strips of dead wood or stones beneath the modules, a habitat can also be created for birds, reptiles, fungi and so on.

In addition, the parallel module rows reduce ground-level wind speeds and thus soil erosion and drying, and the shade from the module rows can further combat drying of the soils.

Another way to improve the environment around the systems is to combine the installation with an extensification of agriculture use and help boost biodiversity even in agriculture-use areas.

Glare is possible with glass surfaces. The topography, existing housing and traffic routes, and orientation of the module substructure must be taken into account in each project. As a guideline, it would be reasonable to expect glare effects of up to 30 min/day and 30 hrs/year. Ultimately, in contentious cases, a glare report must demonstrate that safety for traffic and reasonableness for housing areas.

Glare is a result of reflection and thus the physical principle that the angle of incidence = the angle of refraction. For vertically aligned solar modules, this means that glare can only occur a few metres away from the module and beneath the module’s lower edge.

The small level of overbuilding is a major benefit for bird life – from a bird’s perspective, almost the entire ground area remains directly visible.

There are initial indications that Next2Sun agriphotovoltaics systems are still being used as a habitat by birds of prey (red kite etc.). Additional monitoring at further sites is required to support these initial observations. For ground-nesting birds such as skylarks, the Next2Sun system – like all vertical structures – has a disruptive effect.

The run of module rows (generally in a north-south direction) can affect the wind and thus also the microclimate at ground level (up to three metres high). This may slow down air movement (like a hedge would do), but theoretically could also cause certain wind tunnel effects along the rows.

The PV modules do not produce any noise of their own. The electrical systems may be a potential source of noise.

The Next2Sun system concept only uses string inverters. There are various cooling concepts for these, as can be seen in the private sector. These include active cooling via air as well as cooling via natural convection (air circulation within the housing). The latter produces virtually no noise. The transformer required also involves air that produces a perceptible noise, but it is often drowned out by environmental noise. The location of the transformer station(s) can be planned to ensure that they are a sufficient distance away from the site.

Positive: strips of grass boost biodiversity and thus insect habitats.

Negative: the heat from the systems may have an impact, but we do not yet know what it might be.

Technically, it would be possible to increase the row spacing between the rows. On the other hand, the current system of two stacked modules is the most economic. We are in the process of developing a system with three stacked modules. The height and thus the impact on the environment may vary from project to project.

The low level of overbuilding involved in the Next2Sun system concept means there is no expected impact on soil properties.

Sight lines depend on the azimuthal orientation of the module rows. If the modules have an east-west orientation, there will be a sight line from north to south. The exact visual impact on site is then clarified using suitable visualisations.

No, because a species-rich environment beneath the modules and between the rows is encouraged. This will ultimately have a positive impact when mowing.

In some projects, fencing is provided by our solar fence and no further fencing is required. However, this must be clarified with the responsible insurance provider on a project-by-project basis.

Depends on the site (fence, system size, location)

Yes, hunting is possible within our systems.

Safety aspects

- Safety from wind/storms

- Property insurance

Under normal operations, an N2S system poses no fire hazard. The modules do not reach temperatures that could mean a risk of fire (max. 43°C measured thus far).

As with any electrical system, a malfunction (short circuit / earth fault) may cause a hazard, which is taken suitably into account by the specialist planner.

A separate fire safety concept will therefore only be required if the specific features of the site necessitate it (e.g. due to increased risk of fire in the surrounding area).

The construction of Next2Sun systems means that they are generally very well secured against theft, as the modules are firmly rooted in the ground via the frame system. Only specialist staff will be able to disassemble it. In addition, Next2Sun system concepts are currently protected by a fence.

Our system is designed for up to wind load zone 2. As yet, no systems have suffered any storm damage.

Country-specific regulations apply. A PV system is an electrical system. In order to comply with safety requirements, the area must either be accessible only to specialist staff, or kept permanently safe.

Technical equipment such as inverters is also always closed off and the electrical components are doubly insulated. Using our solar fence as a fence would be an option, which must be clarified on a project-by-project basis.

In principle yes, but it is not recommended, as a ground-mounted system is fundamentally an ‘electrical operation room’.

Insurance costs for the system are broadly the same as for conventional systems.

Projects and project workflow

- Role of Next2Sun

- Project planning and workflow

- Stakeholder network & partners involved

- Legal basis

- Recycling and any deconstruction

Industrial agriphotovoltaics projects, like conventional ground-mounted photovoltaics systems, do not have privileged status outdoors. This means that a development plan must be drawn up with parallel changes to the land area use plan for development to go ahead. The municipality, as decision-maker, is therefore particularly important for the further development of solar power.

The planning process, through to being ready for construction, takes multiple months or even years and involves numerous public bodies and public interest parties. The Next2Sun Group’s system displays numerous benefits in the planning process, as the overbuilt area (i.e. the area not available for mechanical agriculture use) is extremely low at up to 5%.

Depending on the regional building regulations, successful development of a land-use plan is followed by construction approval or an application for exemption. Once all the necessary usage rights under private law have been settled and a binding feed-in point has been set, project implementation can begin.

Next2Sun can serve simply as a product/system supplier, service provider / project developer, or even as an EPC (Engineering, Procurement and Construction) contractor or operator.

The project is generally planned by Next2Sun – this ensures that we can incorporate our wide range of knowledge about vertical systems and avoid any serious errors.

The systems can be executed by an external plant constructor / general contractor. At this stage, if required we provide the building contractor with appropriate consulting services to ensure that the relevant aspects of a vertical agriPV system are also taken into account during execution.

The key stakeholders in our project implementations are:

- Land owner (or leaseholder): plan land use types

- Farmer: put areas to agriculture use

- Municipal representatives: development plans, local council rulings

- Environmental associations: expert opinions, monitoring

- Network operators: planning grid connection for agriPV systems

- Operating companies: managing the agriPV system after construction

- Local community: incorporating local concerns, wishes and ideas

For the majority of our agriPV projects, the legal basis is a development planning process with the relevant municipality.

For secured deconstruction, a deconstruction guarantee is issued to the land owner and/or the local municipality. This ensures via a bank guarantee that upon commissioning, a designated amount (e.g. 25 euros per kWp installed) is available for potential deconstruction. Furthermore, under both urban planning regulations and private law, the operator is obliged to restore the site to its original condition at the end of the operating life.

More detailed information will follow regarding this question

Agri-PV as an investment model

- Financial participation

- Conceptual participation

There are currently three options for financial participation:

- Crowdfunding via the operating company (GmbH)

- Citizen’s energy cooperative loans

- Crowdfunding via the Next2Sun crowdfunding portal >>

Further information can be found on our website under “investments”

In terms of early involvement in the project process, there is an opportunity for various stakeholders and interested parties to present their concerns regarding the project. In addition, during project planning and implementation we also offer optional information events and live demonstrations of the technology on site, giving local populations an insight into agriPV and our system concept. As part of this, we are happy to incorporate locals’ suggestions and concerns into our project planning.

Farms

- What land is suitable?

- Agriculture use

- Land usage for Agri-PV system

AgriPV systems, like conventional PV systems, do not have privileged status outdoors. This means that in this segment as well, from a certain planned size, a development plan must be drawn up with parallel changes to the land area use plan. The low overbuilding of the area and the environmental upgrading and structuring of the area with grass strips below the modules offers benefits in terms of offset requirements – this is usually not required. In addition, another benefit of vertical bifacial systems is that the row orientation can be freely chosen, enabling optimisations as regards landscape and potential glare effects.

In the development plan, the area between the module rows is generally set as agricultural land. In Germany and other European countries (AUT, LU etc.), there are regulations stating that the farmer retains the key area payment for the majority of spaces within agriphotovoltaics systems. The milestone in Germany will be the implementation of GAP – the Direct Payment Implementation Ordinance – from the 2023 claim year, stating that 85% of the area within agriPV continues to be agricultural and will receive EU subsidies. The remaining 15% of the premium rights come from the operators of Next2Sun systems, by agreement.

The maximum building density is 15%. In addition, it must still be possible to work the area using standard agricultural methods, machinery and equipment.

Practical testing from recent years has shown that slight shading changes the agricultural yield in row space. During dry years this can result in increased yields (especially in grassland) due to a higher level of water being available to the plants. In damp and less sunny years, the shade could theoretically also reduce yields to an extent (particularly for crop cultivation). These effects could be stronger in more shaded areas (near to the modules). Further investigations will be conducted into this in coming years.

Yes, all agricultural products coming from the area can be used.

GPS-supported control for agricultural machinery is advisable within a Next2Sun agriPV system, as it enables the entire length to be worked at an optimum distance from the module row.

We have had cattle grazing in our testing facility for two years. In our system, the cable wires are all run in the U-rail (middle crossbeam), ensuring that they are very well protected. Only the inverters require technical protection. This is generally achieved using a simple pasture fence stretched around the inverter. Horses behave similarly to cattle and do not pose a problem for the system. Projects have already been implemented in situations like these in Austria.

The string inverters are integrated into the vertical frame system. In addition, only transformer stations (approx. 2.5 x 3 m) are required above ground on the site. The power is transported from there to the grid connection point via an underground cable.

Thus far we only have experience with grassland farming. In the future, we are planning to establish research projects examining crops. However, we expect potatoes, various types of beets, carrots, legumes, special crops (with the exception of maize) and low-growing cereals (approx. 1 metre) to be very compatible with our system.

Currently, a lawnmower or grass trimmer is used to mow beneath the module rows. This involves high staffing costs, which we want to reduce in the future via tests with a cane cleaner. This device comes from orchard and vineyard cultivation and will automatically fold round the posts to mow. Mowing is performed once or twice a year.

Practical experience from recent years has shown that dirt and dust is cleaned off vertical modules very well by rainfall.

You must keep around 0.5 metres away from the module rows. Grassland management can be up to 20 centimetres from the module row posts, if the tractor has onboard GPS support.

First of all, it should be noted that any intrusion on the landscape with overbuilding and/or sealing of the ground must be counterbalanced. As the overbuilding of up to 5% the area (actually just 1% by the agriPV itself) with the vertical system concept is extremely low and the structuring of the agricultural area with grass strips below the modules offers environmental upgrading, all in all the environment in the area is upgraded.

This far our systems have only been used for grassland farming. Farming machinery for this is equipped with suitable rubber lips, reducing the risk of flying stones to a minimum.

We have not yet identified any module damage following the mowing process. During the prototype phase, we deliberately provoked flying stones (including for potential installation next to roads) and no damage was detected.

In general, we agree in advance with farmers that they will not have to pay for small amounts of damage (e.g. up to 1000 euros).

No offsetting measures are generally required with the Next2Sun system concept. These are separate from functional compensation measures, which are considered in individual cases. These include measures to avoid glare effects and improve landscape integration, as well as to balance the habitats of individual bird species.

The vertical orientation makes it difficult for soiling to be deposited and has a self-cleaning effect when it rains – a key advantage over a conventional system. The soiling level is of course heavily dependent on the type and scope of dual use. With grassland farming, numerous years of experience show that the modules do not need to be cleaned. The plant growth directly beneath the module rows simply has to be cut back once a year to prevent shading. Further investigations will show whether cleaning is required with intensive crop cultivation – however, we do not expect the cleaning requirements to be any higher than with conventional systems.

There has not yet been a final assessment of whether flower and grass strips are eligible for funding (e.g. Under EU greening measures or agri-environmental schemes).

As for conventional PV systems, we have to install a fence around our system. This is required by insurance. However, we can install the vertical system as a fence. This avoids additional fence structures, making agriculture use easier.

Variable spacing between rows of at least eight metres enables various agriculture use concepts. The row spacing is individually determined based on the local requirements and economic considerations.

Land owners such as municipalities, companies etc.

- Prospective yields

- Lease models

Agri-PV systems are basically very well suited for own energy consumption. Due to their generation profile, a significantly better generation-load overlap is achieved than with conventional southern systems. In general, attention must be paid to the individual requirements of the farm.

The lease payment that the operator may pay the land owner is based on the site’s installable power, as is also the case for conventional solar parks. If the row space is ten metres, the installable power using the Next2Sun concept sits at around 50% of the maximum installable power of a conventional south-facing photovoltaic system. As a result, in this scenario the lease would be 50% below the standard market lease costs for a conventional south-facing photovoltaic system on the site. There are of course other parameters that affect the lease amount, including grid connection costs and radiation levels.

The site owner receives land rent from the system operator and can continue to use approximately 90% of the area for agriculture.

Our system is not able to cover the same area with solar modules as a conventional system would. The lease costs are around 800 to 1200 euros per hectare. Farmers are also able to accept a lower lease amount because they are able to further cultivate the site – they can still cultivate 90% of the space whilst also receiving lease payments.

The east-west orientation of the PV module rows means that electricity is primarily produced in the morning and evening. Depending on the module type used, 5% to 15% higher specific electricity yields are achieved per kW. This means that Next2Sun systems are a long way ahead of traditional south-facing photovoltaic systems in terms of yield.

A row spacing of 10 metres can be expected to produce a yield of approximately 0.4 MW per hectare.

This means space requirements of 2.5 to 3 hectares per 1 MW of power, with 98% of the space remaining available for agriculture use.

Frequently asked questions for municipalities and authorities

- Benefits of Agri-PV

- What land is suitable?

- Planning process / installation

- Local acceptance

Agriphotovoltaics falls under the umbrella term ‘open area photovoltaics’ and covers concepts that enable photovoltaics and agriculture to share use of the same space.

The DIN SPEC 91434 technical rule ‘Agri-photovoltaic systems – requirements for primary agricultural use’ can be downloaded for free in various languages from the following link:

https://www.beuth.de/en/technical-rule/din-spec-91434/337886742

Agri-PV systems offer numerous benefits for municipalities and communities to create sustainable value for their citizens and inhabitants with renewable energy sources and draw benefit.

As well as the jobs with local and regional companies created by building and operating the system and the host municipality’s increased importance in the region, an Agri-PV system can exploit environmentally compatible land (whether owned by the municipality or local owners/farmers) without significantly affecting its previous use.

Furthermore, depending on the model, electricity marketing or leasing can diversify or increase income for the municipality and/or owners.

However, an Agri-PV may also take the form of a flagship public participation project for the whole district and thus sustainably reduces reliance on the electricity market. In addition, our experience shows that acceptance of Agri-PV projects is higher than for wind farms.

Almost all areas are suitable unless they are not available for infrastructure projects due to their high environmental importance or overlaps with NATURA2000 areas. Exclusionary planning objectives must also be noted from land area use, regional, and federal planning. Proceedings to obtain permission to deviate from a planning objective are an option in individual cases.

Once a space has been identified, analysed and access to the space ensured, the municipality is approached. We are interested in a collaborative partnership that generally begins with an informative project presentation to a municipal decision-making committee. If a planning process is launched, the project developer covers all of the resulting costs. Involvement by the municipality, its citizens and other public interest parties is hugely important for the planning process. Regularly presenting the procedural steps and potential opportunities for participation will maintain close contact with the municipality.

Yes, as it currently stands a development planning process is always required to install an Agri-PV system.

Planning based on local circumstances, finding an area compatible with the local population, using tree rows / hedgerows as a privacy screen, financial/conceptual participation

According to representative surveys, electricity produced via PV in Germany is the most widely accepted generation profile. There are not yet any population-representative statements regarding Agri-PV. However, initial local surveys show even higher acceptance among populations, as there is no competing for land between agriculture and power generation. Our previous local experiences have been fundamentally positive and supported by municipal representatives.

Frequently asked questions for system builders

- Energy use/feed-in

- Electricity yield / remuneration

- System-specific and installation-specific topics

The maximum distance from the grid connection point depends on the generator output that can be installed. The vertical system concept means that operators have an ace up their sleeve when it comes to communicating with the network operator. Real data has shown that a vertical east-west system can be built without significantly increasing the active AC power at a site that may, for example, already have a conventional photovoltaic system.

The stated service life of a Next2Sun system is 30-40 years. This means that it is longer-lasting than conventional south-facing ground-mounted PV systems (25-30 years).

In our own project developments, we are free and unrestricted when it comes to marketing project rights and implementing the agriPV system. This offers scope for incorporating regional electricity suppliers, energy cooperatives or municipalities. And last but not least, farms and landowners are often interested in investing in agriPV systems on their own farmland.

These depend very much on the size of the system and are approx. 10 – 20 % higher for large Next2Sun systems than for conventional systems. There are significant amortisation benefits from the higher electricity yields, better feed-in tariffs (approx. 0.3 ct/kWh more) and longer service life.

Bifacial PV

Manufacturer: previously Jolywood, now Luxor and Akcome (but not set) –> Criteria must be met

Place of manufacture: China

Material: silicon

PV type: cadmium, monocrystalline or polycrystalline modules? N-type PV

Dimensions 2 x1 metres

The east-west orientation means that systems using the Next2Sun concept feed in power when conventional south-facing PV systems have low production levels. This greatly lightens the load on power networks, particularly at lower voltage levels. Next2Sun systems can therefore feed in power even in areas where networks are running at near capacity from wind and conventional PV systems. The feeding profile of the Next2Sun system matches the daily curve of the electricity price on the electricity exchange. This means that our system also directly benefits from market activity.

The typically lower electricity prices at midday and higher prices in the mornings and evenings mean that our systems using the Next2Sun concept achieve higher average revenue – we obtain market profits on the electricity market that are 5% to 10% higher than for conventional PV systems. Paired with higher yields, this means that the revenue per kW of installed system power increases by up to 25%.

We use our patented elevated system of steel posts, piled using a hydraulic pile driver. The foundation depth depends on the load (wind), the ground conditions and the statics of the frame itself. Generally, no additional foundations are required. In individual cases (underground rock), it may be necessary to use a core drill to make a hole for the foundation, which is then filled with concrete.

The vertical, bifacial glass-glass modules are able to more effectively generate power from diffuse light (when skies are cloudy) than most monofacial modules. In addition, ground with a particularly high albedo (i.e. level of reflectivity) can offer even greater yields. Particularly bright substrates (such as snow) offer particularly high reflectivity.

Modules will be between 1.80 metres and 2.80 metres in height, depending on whether they are arranged as one or two rows.

Each PV module is 2.20 metres in length, and the length of the entire row depends on the site conditions. Any row breaks that may be needed require more specific detailed planning.

A module row will be approximately 0.2 metres deep/wide – the number of rows depends on the available space and the row spacing.

The precise generation profile is dependent on numerous local parameters, making it impossible to state anything for certain. With our systems, we ensure that the generation profile suits the relevant requirements. In general, PV systems produce less electricity in the winter than in the summer as there are fewer hours of sunshine per day.

The frame system is a Next2Sun patent.

The feeding profile of the Next2Sun system matches the daily curve of the electricity price on the electricity exchange. This means that our system also directly benefits from market activity. The typically lower electricity prices at midday and higher prices in the mornings and evenings mean that our systems using the Next2Sun concept achieve higher average revenue – we obtain market profits on the electricity market that are 5% to 10% higher than for conventional PV systems.

In our systems, the module cables are laid in the middle beam (U-rail). This provides the cabling with sufficient protection from weather, grazing animals and wild animals. Module cables can also be given optional additional protection with a plastic cover.

The energy generated at the solar park is fed into the medium-voltage grid. The electricity is then distributed and consumed on a regional level. As electricity flows into the power grid from various generating plants, an electricity mix from various generation profiles comes through at every plug. A vertical, bifacial east-west system can primarily generate power in the mornings and evenings, thus increasing the proportion of renewable energy consumed locally compared with conventional south-facing solar power plants.

Our standard variants have two bifacial PV modules stacked on top of each other. Depending on the wind load, the environmental conditions and economic aspects, it would also be possible to have one or three stacked modules.

Our system hits peak power in the morning and evening, but still produces a certain yield in the middle of the day. If the grid connection point is completely at capacity, it will not be possible to connect a Next2Sun system unless it can be capped during midday hours. If the grid connection point is too overloaded for a conventional system, a Next2Sun system can still be connected.

First the foundation must be examined, as our system is subject to different horizontal loads than conventional solar parks. The systems themselves consist of two different segments. The first four or five posts in a row have a stronger profile. These are piled 2 to 2.5 metres deep and must withstand the wind load incurred at the end of a row. From the fifth post onwards, the weaker piling posts are piled to a depth of 1.6 metres.

Yes, agrivoltaic systems are generally eligible for commission as “special solar installations” in accordance with §37, Para. 1 No. 3 a, b, c. Consequently, they only have to comply with the stipulations of the Federal Network Agency and either have a combined agricultural use of arable land or permanent grassland or the simultaneous cultivation of permanent crops. Installations on areas particularly worthy of nature conservation, such as Natura 2000 areas, are not eligible for commission.

The east-west orientation of the PV module rows means that electricity is primarily produced in the morning and evening. depending on the module type used, 5% to 10% higher specific electricity yields are achieved per kW. This means that Next2Sun systems are a long way ahead of traditional south-facing photvoltaic systems in terms of yield.

The front sides of the module currently have an output of 465 W, whilst the reverse with its tailored HJT modules built in by us has 90% to 93% bifaciality and thus another 430 W of output. With custom products, bifaciality of up to 98% can be achieved. We currently only use HJT solar modules in our systems.

A row spacing of 10 metres can be expected to produce a yield of approximately 0.4 MW per hectare.

This means space requirements of 2.5 to 3 hectares per 1 MW of power, with 98% of the space remaining available for agriculture use.

The expected absolute electricity yields depend on various geographical and also technical parameters at the site. The relative electricity yields per module installed may for example then be dependent on the module’s orientation, the module’s output, and other geographical conditions. Our projects include creating a yield forecast via a detailed simulation before a system is installed.

Didn’t find the answer you were looking for?

Write to us!

We are delighted that you are interested in our products and services!

Send us your query and we will be in touch as soon as possible. Or just give us a call!